In recent years, the demand for stainless steel woven wire mesh has surged across various industries. According to a report by Smith Industries, the market for stainless steel woven wire mesh is expected to grow at a rate of 6.5% annually, reaching $1.2 billion by 2026. This increase is driven by its versatility and durability in applications such as filtration, construction, and automotive sectors.

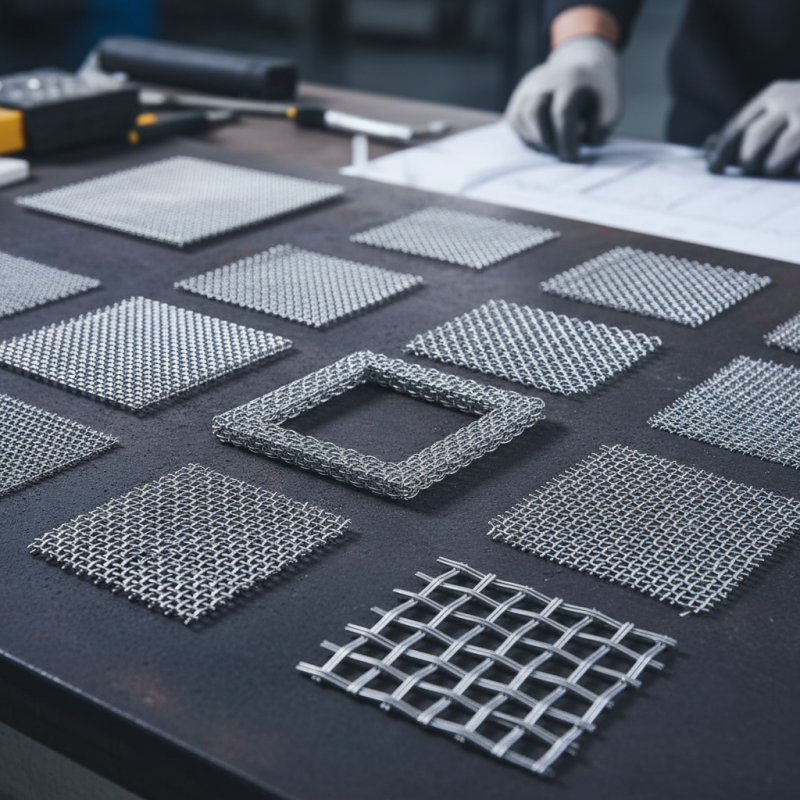

Expert John Thompson, a leading figure in the woven wire industry, once stated, "stainless steel woven wire mesh is not just a material; it’s a solution." His insight underlines the importance of selecting the right mesh for specific needs. However, while the advantages are clear, choosing the best option can be challenging. Various factors must be considered, including mesh size, wire diameter, and specific application requirements.

The landscape of stainless steel woven wire mesh remains complex. Many products in the market may not meet quality standards. In attempting to find the perfect mesh, users might overlook vital characteristics. Therefore, diligence in research is essential to achieve satisfactory results in mesh selection.

Stainless steel woven wire mesh is versatile. It finds applications in various fields. From construction to filtration, it offers unique benefits. In industrial settings, it’s commonly used for sieving and sorting. Its durability ensures longevity, even in harsh environments.

In architecture, it enhances aesthetics. Designers use it as decorative screens or facades. The interplay of light and texture can create stunning visual effects. However, choosing the right wire mesh can be challenging. Factors like wire diameter and mesh opening size must be considered.

Some may overlook maintenance needs and installation complexities. Proper care extends the mesh's lifespan. Understanding specific requirements helps maximize performance. Balancing function and design is crucial. A thoughtful approach can yield impressive results.

Stainless steel woven wire mesh offers numerous benefits in various industries. Its durability makes it ideal for construction and machinery applications. Unlike other materials, stainless steel resists corrosion and can withstand harsh environments. This longevity reduces the need for frequent replacements. In food processing, its non-reactive nature ensures safe food handling.

In various uses, stainless steel mesh enhances safety and reliability. Manufacturers rely on it for filtration, providing clean air and fluids. However, the initial cost can be high, which may deter some businesses. Investing in quality materials usually results in better performance over time.

Another area where stainless steel mesh shines is in architectural design. It adds a modern touch to buildings while maintaining structural integrity. Yet, not all designs can utilize it effectively. Careful consideration of aesthetic and functional aspects is essential. Balancing costs with benefits is a challenge for many industries.

| Industry | Application | Key Benefits | Wire Diameter (mm) | Mesh Size (mm) |

|---|---|---|---|---|

| Food & Beverage | Filtration | Corrosion Resistance | 0.5 | 0.2 |

| Chemical Industry | Separation | Durability | 1.0 | 0.5 |

| Pharmaceuticals | Sifting | Hygienic Design | 0.3 | 0.1 |

| Construction | Reinforcement | Strength | 1.5 | 1.0 |

| Mining | Screening | Wear Resistance | 2.0 | 3.0 |

When choosing stainless steel woven wire mesh, understanding the grades of stainless steel is crucial. Different grades offer varying properties. For example, 304 stainless steel is common for its corrosion resistance and versatility. It is ideal for indoor use and some outdoor applications. In contrast, 316 stainless steel offers better resistance to harsh environments, particularly against chlorides. This makes it suitable for marine use and other demanding conditions.

Tips: Consider your environment. If your application involves exposure to salt or chemicals, opt for higher grades like 316. For general purposes, 304 might suffice.

Another important aspect is the wire diameter. Thicker wires provide more strength and durability but may reduce flexibility. When selecting, think about the mesh opening size. Larger openings allow for greater airflow but may not provide the needed filtration. Balancing these factors can be complex and may require trial and error.

Tips: Don't rush your choice. Test samples if possible. This helps ensure the mesh meets your specific needs and expectations. Every application is unique, so careful evaluation is necessary.

When selecting woven wire mesh, three key performance metrics stand out: strength, corrosion resistance, and durability. Strength is paramount for applications such as construction and filtration. Stainless steel wire mesh typically exhibits tensile strengths averaging around 500 MPa. This makes it ideal for supporting heavy loads while maintaining its shape under stress.

Corrosion resistance is crucial, especially in harsh environments. Stainless steel compositions, particularly those with higher nickel content, provide enhanced resistance to rust and degradation. A report by the International Stainless Steel Forum indicates that properly treated stainless steel can resist corrosion for over a decade in marine environments.

Tips: For projects near water or in wet climates, always select mesh with high nickel content. Regular inspections can help identify weak points in the mesh sooner. Don't overlook the importance of mesh thickness. Thicker wire may offer more durability but at a weight cost.

Durability often ties back to the wire's finish. Processes like electro-polishing can improve performance. However, some treated meshes may be more brittle. This can lead to unexpected failures. Balancing treatment and thickness is essential. It's wise to reassess the material choices based on your specific environment and needs.

The manufacturing of stainless steel woven wire mesh is evolving rapidly. Recent trends highlight increased automation in production. Advanced techniques enhance precision and efficiency. This shift allows for cost reductions, yet may lead to job losses. Balancing innovation with workforce impacts is vital.

Sustainability is another key focus. Many manufacturers are exploring eco-friendly materials. Recycled stainless steel is becoming more popular. However, sourcing can be a challenge. Some companies face delays and quality issues with recycled materials. This raises questions about true sustainability in practice.

Additionally, the design of woven wire mesh is adapting to new industries. Customization is in demand across sectors. Architects and engineers are pushing boundaries with creative applications. There remains a tension, though, between standardization and innovation. Finding the right balance is essential for future growth in this field.

Let us help you get started with our superior LED lighting products.

Get all the latest news from BrightLED.

Copyright © Bright LED. All rights reserved.

STAY CONNECTED